Please note : A level of 100 ppm Pt in a filtrate at 1000 USD/troz means a value of approx. 3220 USD/m3 !

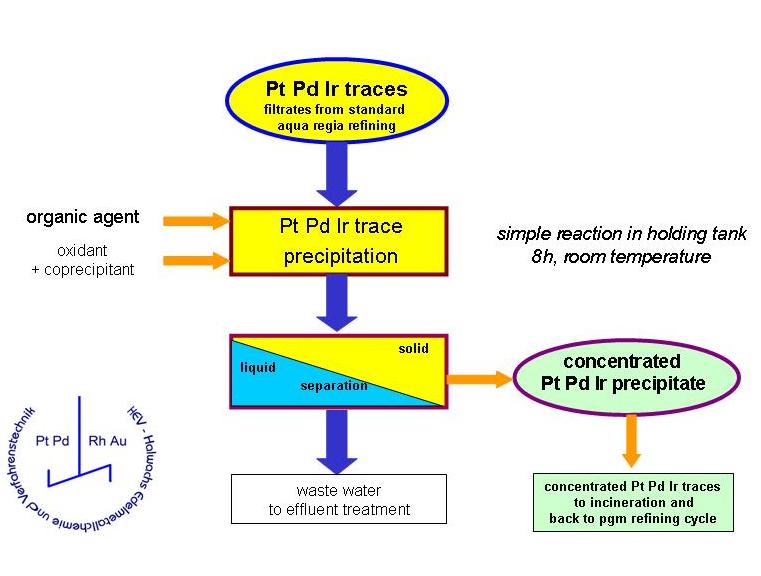

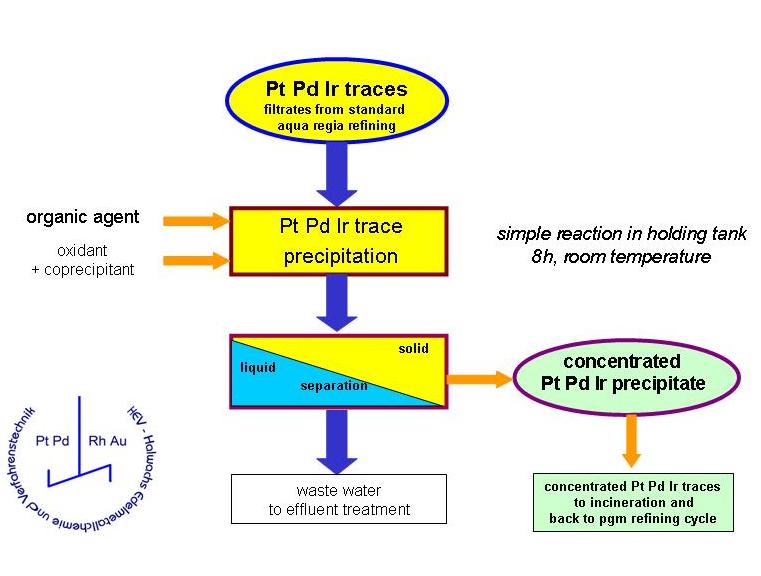

Collective PtPdIr Trace Precipitation By An Organic Agent

(selective for Pt Pd Ir, selective against Rh Ru, Cu Ni Pb and other base metals)

some globally active refiners still rely on old pollutive aqua regia refining; you too ?

this process can help to recover values and minimize waste

useful separation scheme for |

typical process data |

|

typical pregnant liquor /feed |

|

benefits |

typical pregnant liquor /feed |